FEEDER

Three pick up and four forward suck heads with angle adjustment.

Preloading device with rail cart and scaled gate

Manually side adjustment of pallet table (+/- 40 mm)

Non-stop feeder with automatic pile lift

Side blowers adjustable according to sheet size for smooth feeding.

FEED TABLE

Four front lay with dial read out at the operation side, and adjustable in pair.

Pull and Push convertible Side Lay (OS and OOS) with photo sensor sheet arrival control

Two modes of Double sheet detector, ultrasonic or mechanical type alternative on stock range.

Ultrasonic type for paper and cardboard, mechanical for flute corrugated board.

DIECUTTING SECTION

Precision worm gear crank toggle driving system to ensure smooth and dynamic lower platen movement

Short stroke movable platen, driven by eccentric worm gear and toggle mechanism allows large motion angle hence minimum number and size of nicks at reasonable max. production speed.

Precision stationery upper platen.

State-of-art 3 cam index gripper bar drive system to ensure smooth and precise gripper bar intermittent movement.

Pneumatic clutch/brake for main drive system.

Motorized cutting force setting by push button.

Digital strain gauge die cutting pressure tonnage display at HMI with adjustable pressure limit protection.

Seven high precision alloy gripper bar.

High quality pre-stretched gripper bar drive chain.

Torque limit safety clutch to protect the index drive system in case of gripper bar crash.

Double cam driven gripper opener and front lay swing frame without position restore spring for smooth and accurate sheet register and take off.

Pneumatic push button die chase locking mechanism to ensure safe and operator friendly changing of the die.

5mm hardened cutting plate or 4+1mm sandwich plate (optional) on top of 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment for quick set up and make ready.

Automatic main chain greasing system .

STRIPPING SECTION

Complete set of stripping tools with upper and lower stripping pins

Centre line system for quick stripping die set up

Integrated Quick Locking System

Automatic quick locking device for the upper tool integrated in the machine

Funnel for waste guidance

Efficient and smooth cam running curve drives the stripping tooling with large motion angle to ensure clean and tiny stripping at speed

Pneumatic quick lifting device for upper frame

DELIVERY SECTION

Automatic delivery with non – stop curtain. This curtain moves into the delivery to catch the arriving sheets during the pile exchange

Five section brush brake each section angle adjustable individually

Air blower to press down the sheets

Rare and side joggers with easy position adjustment

Safety device to prevent the steel pile plate from clamping on the foot when it reaches at ground level

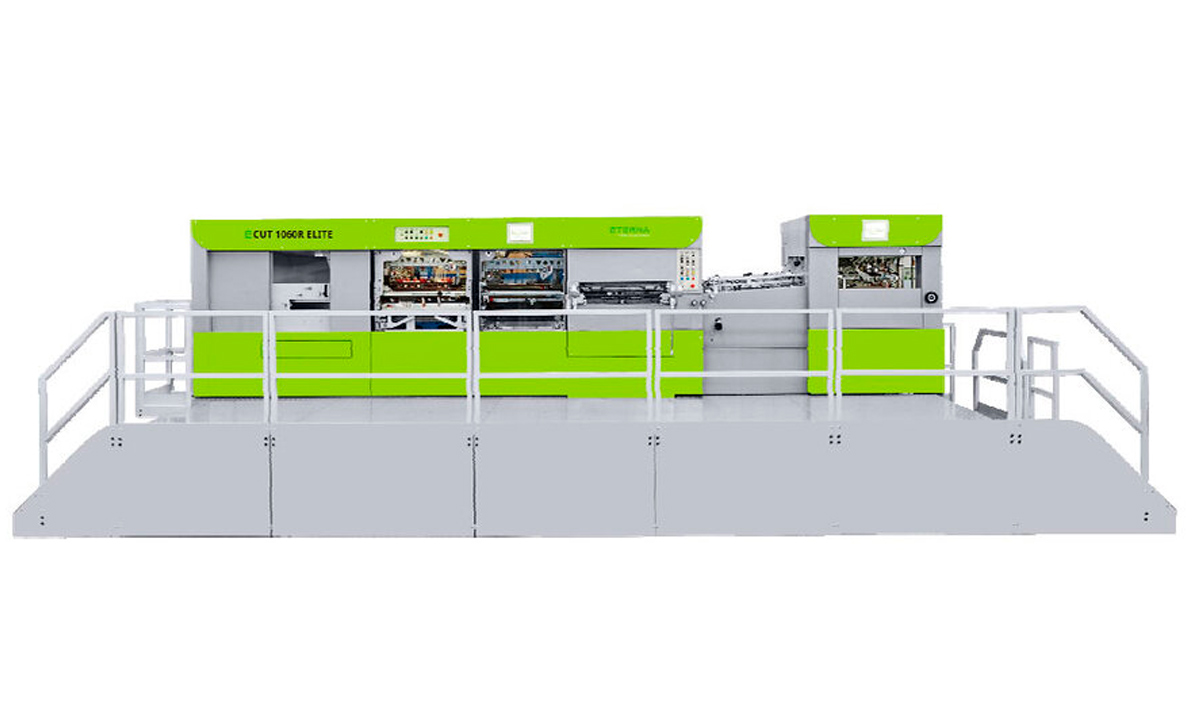

Maximum Sheet Size

: 1060 × 760 mm

Minimum Sheet Size

: 400 × 350 mm

Maximum Cutting Size

: 1060 × 745 mm

Inner Chase Size

: 1080 × 770 mm

Stock Range

1. Paper (depending on quality), min.

: 90 g/m2

2. Board (depending on quality), up to (*)

: 1000 g/m2

3. Corrugated Board, up to (*)

: 4 mm

(*) Carton acceptable wrap: 2% of the width wise sheet

Minimum Gripper Margin

: 9~17 mm

Cutting Rule Height

: 23.8 mm

Minimum Width of Double Cuts

: 5 mm

Maximum Mechanical Speed

: 8000 cycles/hour

Maximum Cutting Pressure

: 260 Tons

Maximum Pile Height at Feeder – Normal Mode

: 1800 mm

Maximum Pile Height at Feeder – Non-stop Mode

: 1520 mm

Maximum Pile Height at Delivery

: 1550 mm

Total Power Required

: 23 KW

Main Motor Power

: 15 KW

Net Weight of Machine

: 20000 kg

Machine Dimensions

:7420 (L) × 4520 (W) × 2640 (H) mm (incl. Catwalk)

Utiliza sólo tintas e insumos originales

Utiliza sólo tintas e insumos originales